⚡TL;DR

Galy is a Boston-based biotech company that grows real cotton from plant cells in bioreactors, producing natural fibers without farming, land, or weather dependence.

🧪👕 From Cells to Shirts. Galy grows real cotton directly from plant cells in bioreactors, skipping farms, fields, pesticides, and weather to make natural fibers faster, cleaner, and on demand.

🌍☕🌿 Cotton Is Just the Beginning. The same cellular platform can be applied to other high-impact crops like coffee, cacao, and medicinal plants. We can produce scarce, climate-sensitive materials without land constraints.

🛍️🚀💸 From Lab to Sock Drawer. Galy has raised $65M+ in funding and secured partnerships with major global apparel players including H&M and Inditex (Zara), with real momentum toward commercial scale.

🙌⚡ Why We Say Hell Yeah. Cotton is one of the world’s most resource-hungry and ethically complex crops. Galy’s approach is dramatically faster, vastly more resource-efficient, independent of land and weather, and opens the door to a future where we grow materials anywhere… even off-planet.

The $40B cotton industry isn’t so fresh, so clean clean

Yes, lab-grown anything is interesting. We eat Impossible Burgers and Dan rocks a lab-grown diamond bellybutton ring. But, lab-grown meat and diamonds make intuitive sense: they address scarcity, ethics, and environmental harm. Cotton feels different. It’s plant-based. It’s everywhere. It’s soft and fluffy. But abundance doesn’t mean efficiency - and cotton is a system that scaled before we understood the cost.

Turns out, cotton is one of the most resource-hungry crops on Earth. A single t-shirt takes 2,700 liters of water (roughly what one person drinks over 3 years). Cotton occupies just 2.5% of global farmland, yet accounts for 16% of global insecticides. It’s also finicky and sensitive to climate volatility (drought, floods, crop failures, etc.)

Then there’s labor. The International Labour Organization estimates forced or child labor remains embedded in parts of the global cotton supply chain, particularly in regions where traceability is weak. Add geopolitical friction like tariffs and trade bans, and cotton starts to look less like a “basic input” and more like a fragile liability.

Agriculture, but for cells

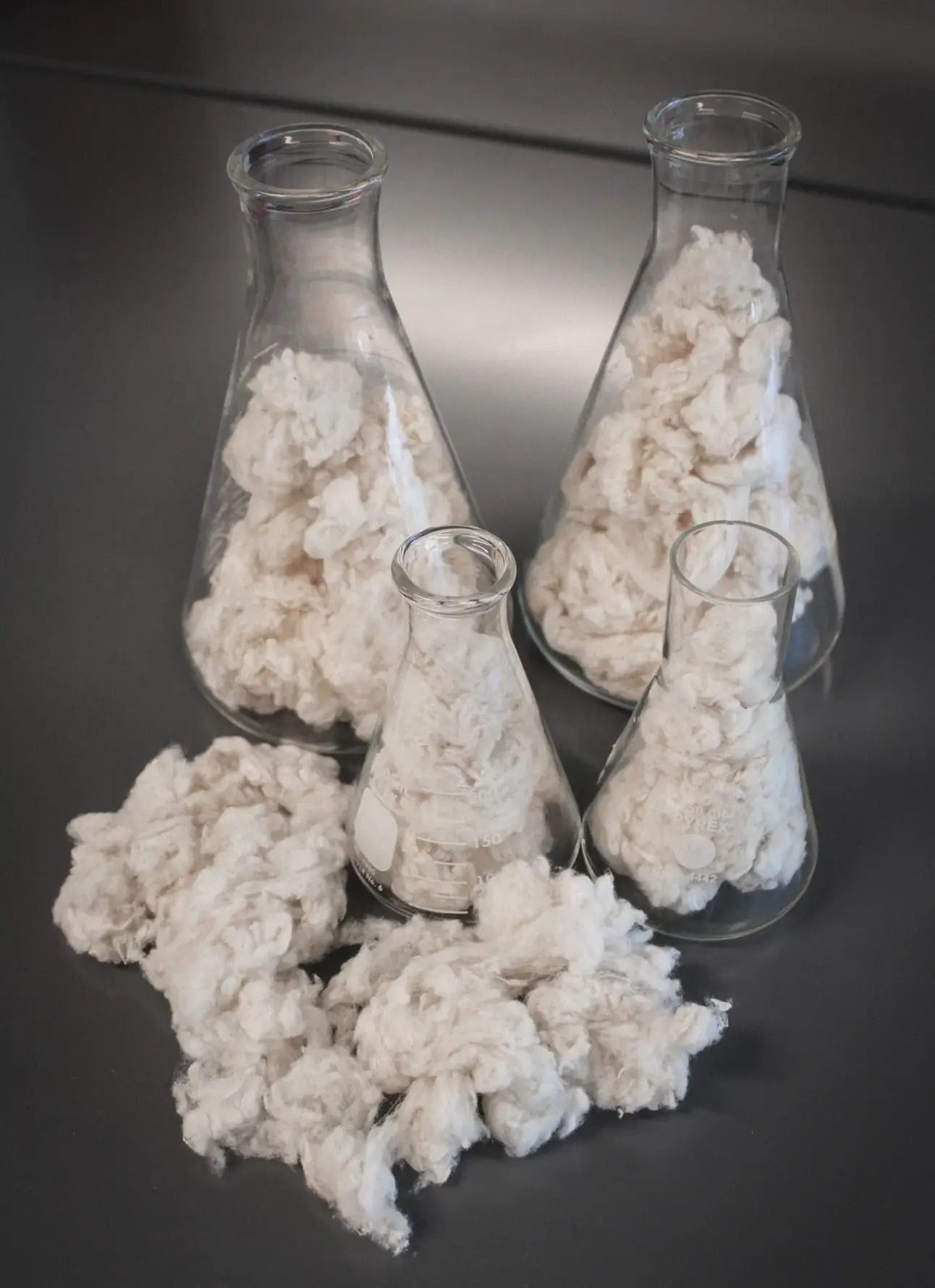

Instead of growing an entire cotton plant (roots, stems, leaves, etc) just to harvest fibers from a single boll, GALY grows only the part that matters: the fibers themselves.

Here’s the simplified version of how it works:

Cell Sampling

Live cotton cells are collected from existing plants and preserved via cryopreservation, creating a stable, renewable starting point. One sample can theoretically supply production indefinitely.

Bioreactor Growth

Those cells are grown in bioreactors under tightly controlled conditions: temperature, nutrients, oxygen, and growth signals are optimized continuously. Instead of reacting to weather, pests, or soil quality, everything happens indoors, on demand.

Fiber Formation

The cells transform and elongate into cotton fibers much like they would in nature, though without the rest of the plant. Fibers are harvested once they hit target length, strength, and quality specs.

The result is real cotton. Not a fake, kind-of cotton blend that chafes when running. Think of it as precision fermentation, but for textiles.

Hell… what else can can we grow in the lab?

Cotton is just the start. If you can grow fibers directly from cells, the obvious next question is: why stop at clothing? GALY is already exploring other crops where we currently grow entire plants just to harvest a tiny fraction of usable material.

Coffee. Cacao. Medicinal plants. High-value botanicals.

Also, as we touched in our pieces on Ecovative (lab-grown mycelium products) and Lignosat (wooden satellites), if humans want to escape Earth for extended periods of time, we cannot be dependent on bringing everything we need from home. As we terraform other planets, we will need to think of rows of cotton fields are the best use of land (rather than food). Lab-grown alternatives may be preferable.

In 2024, Galy raised a $33M Series B led by Breakthrough Energy Ventures, with strategic participation from H&M Group and Inditex (Zara), a strong signal that major apparel players are betting on lab-grown cotton. Inditex also took a direct equity stake earlier in the year. On the commercial side, Galy has secured multi-year offtake agreements, including a reported $50M, 10-year supply deal for medical-grade cotton, as it moves its flagship Galy Cotton toward pre-industrial scale and expands its plant-cell platform beyond textiles.

⚡Why we said hell yeah!

We here at Hell Yeah HQ are clearly excited about reimagining entire production systems. In addition to Ecovative, we also liked Future Fields which is rethinking protein production entirely. It’s these types of moonshot system changes that truly catapult humanity forward.

Also, we’re fans of agriculture, as it employs ~1B people (about 28% of the global workforce)! So, it took us a minute to get comfortable with a technology that could disrupt the hundreds of millions of people who work in cotton farming, processing, and manufacturing. A disruption at this scale isn’t just a cool buzzword to throw at venture capitalists, it could have major sociopolitical implications.

So at it’s core, what we like about GALY is it serves as a true kick-in-the-ass to make traditional agriculture more sustainable and efficient. If cellular agriculture uses up to 99% less water, with 97% less land, 77% lower CO2 emissions, with zero pesticides or insecticides - then the ag industry needs to adopt better practices. The traditional farming industry can’t fight this like how the beef industry fought Impossible by criticizing fake meat (which it is). Lab-grown cotton is REAL cotton, so instead of fighting technology - we hope this serves the larger agriculture industry with a real wake-up call about how to improve.

Otherwise, we’ll find a way to employ land farmers as cellular farmers, and use our land for more regenerative forests and dog parks.

But we’re still a long way off from that. GALY (and other cellular agriculture companies) need to scale, cut costs, and prove dependable enough to challenge the status quotton (🎯 we had to)? Until then, we can’t wait to try a test-tube shirt.

Hell yeah.

Dive in Deeper

Hit us up if you’d like to learn more or if you have suggestions for future features.

Forwarded this email? Subscribe at hellyeah.xyz

Don’t forget: life’s too short to be an Eeyore.